The parts are manufactured with high precision equipment, in Xinbo we have three “do not” that is: Do not accept the order that is out of our quality capability; Do not make unqualified parts; Do not ship out unqualified parts.

Competitive price and reliable quality will be offered, sometime in order to save the cost, the extrusion die/forge mould will be made, although there’s tooling cost, but the parts’ unit cost will be much lower.

Titanium is a widely used material in the aerospace and medical industries due to its special properties. Machining operations of titanium alloys are considered to be difficult, due to its relatively high tensile strength, low ductile yield, 50% lower modulus of elasticity (104 GPa) and approximately 80% lower thermal conductivity than that of steel. Except that Titanium‘s heat conductivity coefficient is 20% of steel, so the cutting tool can be overheat when cutting the titanium parts, overheat will easily cause the cutter’s strength decline.

The difficulty is how to control warpage, and how to make meet the tight tolerance, our experienced engineering team has rich experience about plastic parts machining.

Finishing may cause dimensions out of some of the very tight tolerance, we will notice customer if the finishing will cause the dimension/tolerance issue, we offer: heat treatment, bead blast, anodize, Aldine, Electrolytic Polishing, barrel grinding, PVD coating, brushing, CNC/laser engraving, silk printing, laser engraving.

Machining according to customer’s needs, for example: deburring, keep the sharp edge, install the dowel pin, laser engrave on parts, multi finishing on the same part, thickness of the plating.

Through many years of experience in machining with overseas customers, Xinbo has accumulated a wealth of knowledge, the tolerance can meet ISO2768f and IT6, GD&T also cab be inspected in house, the certification of material and finishing can be offered as customer’s requirements.

2-3 days for machining and 3 working days for shipping(DHL, FedEx), this can meet customer’s urgent prototype/sample requirement, and save customer’s R&D time.

Shenzhen Xinbo Precision parts Co., LTD committed to meet the tight tolerance and high-quality requirements of customers, to help customers win the market.

In Shenzhen and Dongguan we have a group of manufacturing parters in the field of CNC milling, turning, vacuum casting, finishing, extrusion, die casting, stamping, bending and injection molding.

Our team members has more than 20 years manufacturing experience. We know the advantages and disadvantages of each of our manufacturing partners, so that we can balance "Quality" "Price" and "Lead time" and avoid risk to complete the order smoothly.

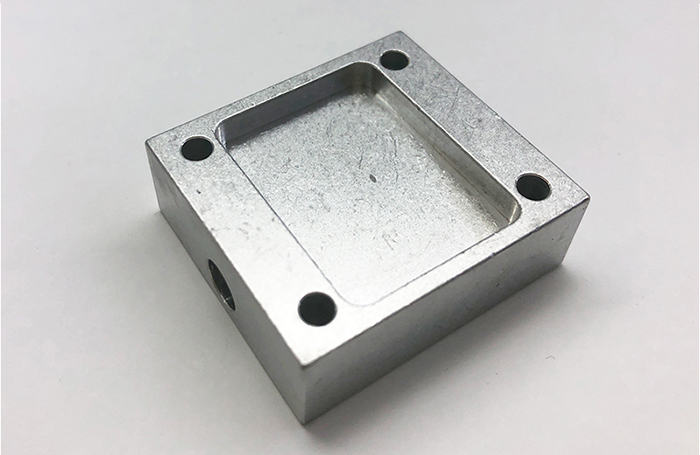

This part’s shape is simple, process is milling, material is 6082 aluminum, tolerance is ISO2768m, finish is barrel grinding. Since it’s high volume, the unit price is very low.

These parts’s are made by live tool turning, it’s a high efficient way to to make these kind of parts, so the machining cost is very low.

Prototype machined parts: compares with 3D printing, machined parts could meet higher tolerance, for example for metal parts could meet micron grade tolerance, for plastic parts, except that, the machine parts could have higher roughness, normally at at least Ra1.6 or Ra3.2, printed parts have much rough finish. Except that machined parts have more available material for selection.